Sound the Environmental Alarm

A scientific study published in the 2018 issue of the “Royal Society Open Science” journal reported that the current quantity of plastic waste in the oceans ranges from 75 million to 199 million tons, constituting 85% of the total weight of oceanic debris. This significant volume of plastic waste serves as a compelling warning to humanity. Without effective intervention measures, it is projected that the annual input of plastic waste into aquatic environments will nearly double by 2040, reaching an annual range of 23 to 37 million tons.

Biodegradable Straw Making Machine

According to the most recent report by the United Nations Environment Programme titled “From Pollution to Solution: Global Oceanic Garbage and Plastic Pollution Assessment,” global plastic production amounted to 9.2 billion tons between 1950 and 2017, with approximately 7 billion tons of that becoming plastic waste. Despite this, the worldwide recycling rate for plastic is less than 10%. Biodegradable straw making machines emerge as a promising and forward-looking solution to address this predicament.

As of 2022, more than 140 countries including France, South Korea, Germany, China, New Zealand, and Africa have clearly formulated or issued relevant plastic ban and restriction policies. Many international conventions and international organizations are also taking action to support the international community in reducing and eliminating plastic products, encouraging the development of alternatives, and adjusting industrial and trade policies to reduce plastic pollution.

Biodegradable straw making machines mark a paradigm shift in sustainable manufacturing practices. The machines use environmentally friendly materials, such as plant-based polymers or starch, to create biodegradable straws that naturally break down over time. Compared to traditional plastic straws, which take hundreds of years to decompose, these biodegradable straws break down and harmlessly dissolve into the environment in just tens of days or months.

Environmental Benefits of Biodegradable Straw Making Machines

1. Reduction of Plastic Pollution

Biodegradable straw making machines produce straws from materials that naturally decompose, reducing the reliance on traditional plastic straws. This helps in combating plastic pollution, especially in marine environments where plastic waste poses a severe threat to ecosystems.

2. Minimization of Non-Biodegradable Waste

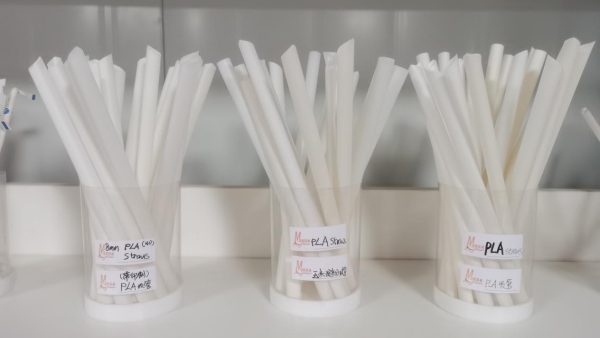

The biodegradable straw making machine uses PLA (polylactic acid), a degradable material extracted from starch, to make straws. This kind of straw can naturally decompose within a certain period of time and eventually become a non-toxic and harmless substance. More importantly, it also has a similar use feel to traditional plastic, making it an ideal alternative to traditional plastic straws.

3. Lower Carbon Footprint

Biodegradable straw making machines often incorporate sustainable and energy-efficient production processes. By utilizing renewable resources and adopting eco-friendly manufacturing practices, these machines contribute to a lower overall carbon footprint compared to conventional plastic straw production.

4. Preservation of Natural Resources

Traditional plastic straws are derived from fossil fuels, contributing to resource depletion and environmental degradation during extraction and processing. Biodegradable straw making machines typically use materials derived from renewable resources, helping preserve natural ecosystems and reduce the environmental impact associated with fossil fuel extraction.

5. Biodegradability and Soil Enrichment

Biodegradable straws, when disposed of properly, break down into natural components over time. This not only prevents long-term environmental harm but also enriches the soil as the materials decompose, contributing to a healthier and more sustainable ecosystem.

6. Promotion of Circular Economy

The use of biodegradable materials in straw production supports the concept of a circular economy, where resources are used, reused, and recycled in a closed loop. This minimizes waste generation and promotes a more sustainable approach to resource management.

Biodegradable straws stand as environmentally conscious alternatives to single-use plastics. In 2015, a conservation organization dedicated to sea turtles released a compelling video depicting the extraction of a plastic straw from a sea turtle’s nostril, raising awareness about the environmental hazards associated with single-use plastic straws. Considering the imperative for safety, hygiene, and convenience in beverage consumption, the advent of biodegradable straw making machines presents a promising prospect to replace the conventional single-use plastic straw manufacturing machines. This transition holds the potential to significantly mitigate plastic pollution.

Conclusion

In conclusion, the advent of biodegradable straw making machines heralds a new era in the battle against plastic pollution. Their potential to make a substantial difference to the environment is undeniable. By embracing this innovative technology, we take a step closer to a more sustainable and harmonious coexistence with our planet. The journey towards a plastic-free future begins with choices, and biodegradable straw making machines offer a compelling avenue for positive change.

Biodegradable Straw Making Machine Manufacturer——Marrow

For three decades, Nanjing Marrow Machinery has played a significant role in the eco-friendly straw machinery industry. The company has dedicated substantial resources to research and development, aiming to provide the highest quality and cutting-edge environmentally friendly straw production equipment for manufacturers.

Our biodegradable straw machine, designed for environmental sustainability, incorporates special patent technical design screw. It exhibits versatility by accommodating various mainstream straw materials available in the market. Throughout the production process, this machinery enhances the mixing and plasticizing effects of raw materials, ensuring the uniformity of the produced materials and, consequently, the quality of PLA straws.