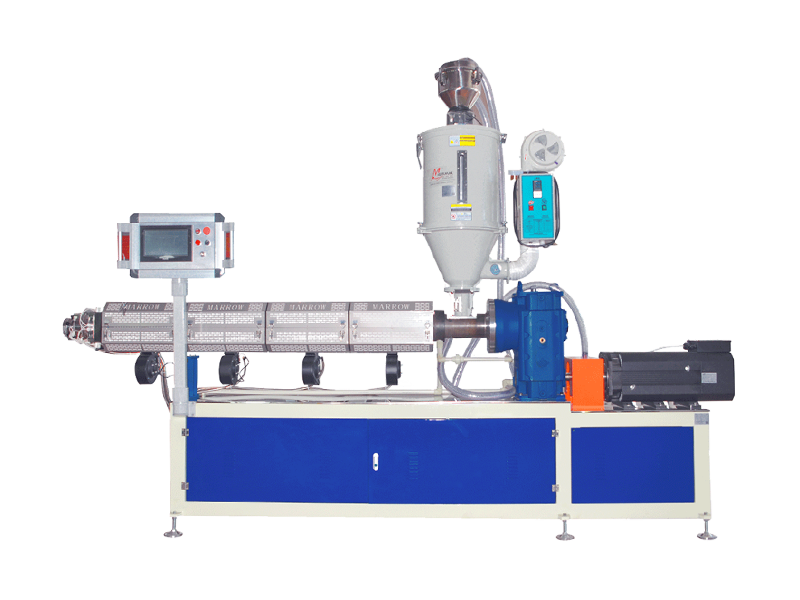

PLA/PHA Straw Extruder

PLA Straw Making Machines For Sale

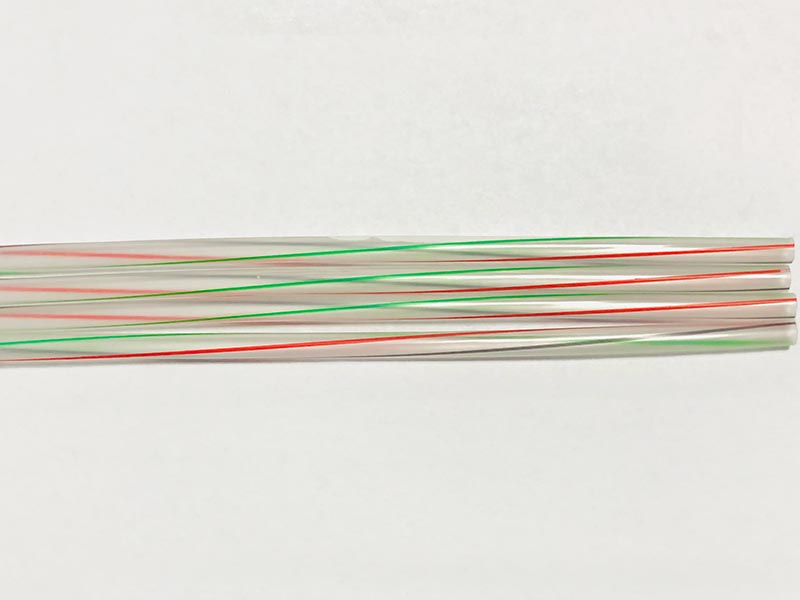

PLA straw extruder is the most important machine among the straw making machines that people talk about. Our machine can produce monochrome, bicolored, and tricolored color straws. Regarding the color preferences for the straws, our machines can meet the requirements of most of your customers. You’re welcome to take a look at the machines you’re interested in, or you can reach out to us directly. We’ll get back to you as soon as possible.

Poly(lactic acid) (PLA) and polyhydroxyalkanoate (PHA) are two types of biodegradable materials used in the production of eco-friendly straws, offering alternatives to traditional plastic straws. These materials are part of a broader movement towards reducing plastic waste and its environmental impact.

The new fully automatic PLA extrusion production line developed for the production of environmentally friendly PLA/PHA materials is designed and manufactured according to the characteristics of PLA/PHA materials.

It offers good plasticization and temperature control, with high efficiency and energy savings.

Technical Features Of PLA Straw Making Machines:

- The specially designed PLA screw length-to-diameter ratio is 33:1, and the 146-type hard tooth surface reducer is suitable for PLA and PP materials. The machine capacity is larger and the straw size is stable.

- The traction device can be a belt or a roller and can be customized with dual rotary cutters. Cutting angle: 90°/45°, 90°/60°.

- Far-infrared radiation heating is efficient and energy-saving. A cooling fan keeps the heating temperature stable.

- Conveying device (can be selected according to needs)

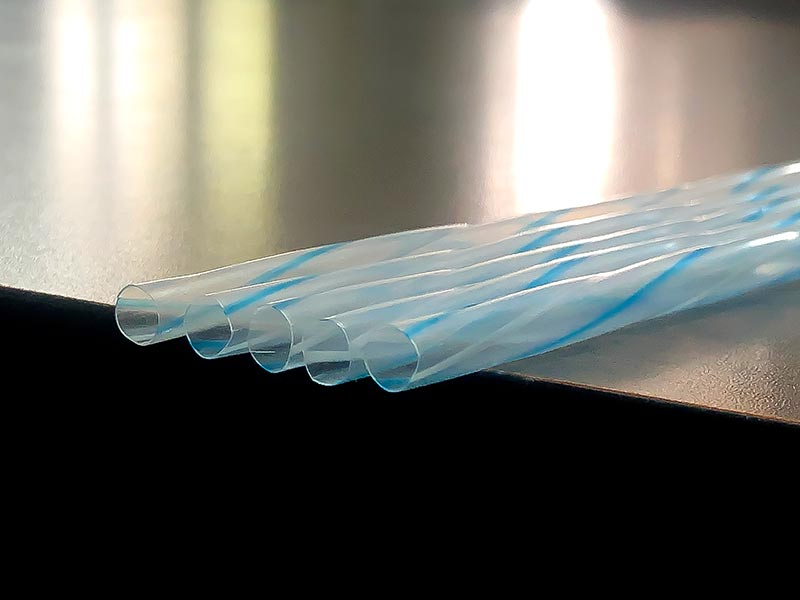

Straw Examples By Marrow Automatic Straw Production Line

Straws By Marrow Straw Making Machine

PLA Straw Making Machine Specifications:

| Model | ML11 | ML12 | ML13 | |

| Feature | Material | PLA / PP / PE | PLA/PP | |

| Color | 1 | 2 | 3 | |

| Straw diameter | φ3.0 ~ φ12 mm | |||

| Thickness | 0.10 ~ 0.35 mm | |||

| Straw length | 80 ~ 300 mm | |||

| Stripes | Straight / Helical | |||

| Capability | 400 ~ 1800 pcs/min | |||

| Extruding output range | 30 ~ 100 kgs/hr | 20 ~40 kgs/hr | ||

| Extruder | Main Screw diameter | Φ50/Φ65 mm (BM Screw) | φ50 mm ( BM Screw) | |

| Screw L/D | 33:01:00 | 1.375694444 | 33:01:00 | |

| Main driving motor | 22/30 Kw (Servo motor) | 18.5 Kw (Servo motor) | ||

| Automatic thermo-controller | 6 sets | 8 sets | 11 sets | |

| Water Cooling tank | Forming device | 1 set | ||

| Base frame material | 304 Steel stainless | |||

| Blow dry device | 1/3 set | 1 set | ||

| Take up & Cutting Unit | Belt take-up unit | 1 set | ||

| Motor | 0.75kW×1(VFD) | |||

| Cutting knife unit | 1 set | |||

| Angle of port | 90°/60°/45° | |||

| Digital counter | 1 set | |||

| Others | Air compressor | 1.5kw (choose) | ||

| Dimension LxWxH | 9m×1.2m×1.6 m | 8.5m×1.2m×1.6 m | 8.5m×1.4m×1.6 m | |

| 13.5m×1.4m×1.6 m | ||||

| Machine weight | 2500/2800 kgs | 2200 kgs | 2400 kgs | |

Advantages Of Marrow PLA Straw Extruder

Special patent technical design screw L:D (33:1) for PLA material,all straw materials on the market are applicable.

Extrusion capacity up to 100kg/h(1800 straws /min)

The service life of the machine is more than 20 years

30kw high efficient & saving energy servo motor, effectively reduce the grammage error of straws, and ensure the efficient and stable production of PLA straws.

The use of a number of patented technology design, improve the comprehensive performance of the straw machines, to ensure the stable and efficient operation of the straw making machines.

After the straw machine arrives at the straw factory, it only needs to go through a simple trial machine to produce qualified straws, which greatly reduces the waste of straw raw materials in the process of trial machine.

Experienced operators to provide services on site.

Straw machine experts teach straw machine application methods, professional video training courses for online training.

Why Choose Marrow

For many years, Marrow has been developing high-quality, high-efficient, and economic straw production machines to promote the development of the straw production industry. We take pride in helping grow your business.

- Quality Parts For Machines

- Patents & Certificates

- On-site/On-line Technical Support & Training

Customer Reviews

With over 1000+ 5-Star reviews, Marrow has the highest ratings in the industry.We Have Served For 1000+ Straw Production Businesses In The World.

How Does An Extruder Turn PLA Into Drinking Straws?

PLA straw production lines typically involve a series of processes, including straw extrusion, cooling, and cutting.

Here’s a general overview of how a PLA straws production line works:

The Main Extruder refers to the PLA straw extrusion machine, which is primarily used to extrude and shape PLA straw material. The straw material is fed from the hopper into the barrel with a screw inside. The screw functions to heat and melt the straw material, while also mixing and homogenizing it to achieve full plasticization. We use our self-developed screw for our straw extrusion machine, which is designed based on the characteristics of PLA material and over 20 years of experience in straw machine production and research. We have secured multiple patents for our innovative screw design. With a length-to-diameter ratio of 33:1, this screw is capable of handling PLA material and a wide range of straw materials available in the market. It allows for precise control over the properties of the extruded material, ensuring consistent output throughout the production process.

After extrusion, the straws are in a hot state. To achieve their desired shape, a cooling water tank, referred to as Vacuum Calibration and Cooling, is utilized. This tank effectively cools down the extruded straws, enabling them to solidify and maintain their desired form.

The straws are cut using a Haul-off and Cutter machine, and the length of the produced straws is regulated by adjusting the traction speed and cutting speed of the machine.

Following the cutting process, the diameter, length, wall thickness, or weight of the cut straws are measured manually. If they meet the production requirements, they are deemed to be essentially qualified.

At this stage, the production of straight straws is completed.

If there is a requirement to produce bent straws using PLA material, an additional step of straw forming is introduced after Step 3. Cutting. The process of forming flexible straws involves the use of a specialized straw-forming machine. Different shapes of straws necessitate the use of corresponding machines designed specifically for those shapes. For instance, a Z-shaped straw-forming machine is employed for Z-shaped straws, an expandable straw-forming machine is utilized for expandable straws, and a U-shaped straw-forming machine is employed for U-shaped straws.

The PLA straw crystallization machine is used to subject the produced straws to a secondary high-temperature heating process, which improves the temperature resistance of the PLA straws.

Straight straws, commonly used for milk tea (PLA straws), can be directly packaged after production using a straw-aligning machine and an incline conveyor to transport them to the straw packaging machine.

Milk tea straws are typically packaged individually, so a machine designed for individual straw packaging, such as the ML31D, is used.

After individual straw packaging, if there is a need to group multiple straws together. multiple straw packing machines like ML39E will be used.

The 3 Key Factors That Determine the Performance of PLA Straw Extruder

1. Good plasticizing effect.

Ensure that the straw material after the distribution of uniform temperature heating, reach the flow state, and has good plasticity.

Benefits:

a. A good plasticizing effect of the straw extruder screw indicates that it can effectively melt the straw material into various specifications of straws and produce multiple sizes of straws. It can also be used to produce products like pen cores and pen barrels.

b. A good plasticizing effect of the straw extruder improves product quality. The produced straws are more uniform, with more precise dimensions. The surface of the produced straw products is smooth, without defects such as bubbles or burrs. The quality is more stable, meeting the high-quality requirements of customers for straw products.

2. Large amount of extrusion

It enables large daily output of straws and ensures good quality straws.

3. Precise temperature control

In the case of low precision, the temperature is difficult to control and requires multiple debugging, which is likely to waste a lot of straw material.

Choose Marrow PLA Straw Extruder!

Marrow PLA straw extruder adopts a far-infrared high-efficiency energy-saving heater and is excellent in plasticization. It utilizes a high-efficiency energy-saving servo motor for direct drive, ensuring large extrusion output and stable extrusion of straw material.

The main unit is equipped with a touchscreen control, PLC, and temperature control module, providing high-precision temperature control. The cutting process utilizes a servo motor system controlled by a touch screen and PLC, allowing for a wide range of length adjustments with minimal length deviation. The production data meets the requirements for intelligent management in the factory.

Our PLA extruder is an intelligent specialized equipment for producing various PLA and PP beverage straws. With the capability to interchange certain components, it can produce precision small-diameter pipes and small-sized special rods.

Marrow extruder is the preferred choice of numerous domestic customers! Marow Machinery provides equipment and professional technical support to over 500+ domestic and 200+ international customers worldwide.

How To Inspect and Maintain PLA Straw-Making Machine?

Many PLA straw production factories encounter issues with low production efficiency and instability when using PLA straw extruders. This is often due to a lack of timely inspection and maintenance of PLA straw extrusion machine. Here are some tips for maintaining and repairing PLA straw making machine.

- 1.Regularly open the gearbox cover and check the oil level. Generally, it is recommended to check it once a month and change the oil every two months.

- 2.Periodically tighten screws, nuts, and other components to improve the production stability of the straw extruder.

- 3.Apply high-temperature resistant lubricating oil or grease to bearings, rotating structures, and moving parts regularly. Prolonged dry running can affect the equipment's lifespan.

- 4.Check the lubricating oil level in the reducer and replenish it as necessary. It is generally recommended to add oil monthly.

- 5.Keep the gear and chain drive parts clean. Apply lubricating grease every six months to ensure the machine operates smoothly.

These are the key considerations for drinking straw making machine maintenance. If you have any other questions about drinking straw making machines, feel free to message us. Marrow is always happy to assist you!