PLA Straw Production Line

China PLA Straw Making Machines For PLA Straw Production

Get The Best Straw Production Solutions Right Now!

What's Your Industry? What Product Do You Make?

No matter what your application is, you’ll get the best solution from Marrow.

Applications:

1. Food industry: beverage straws, sugar sticks, coffee stir sticks, oral liquid medicine straws, etc.

2. Other industries: signature pen refills, nozzle tubes, balloon sticks, small flag sticks, cotton swab sticks, medical tubes, etc.

With 30+ years of experience in straw-making machines R&D, our state-of-the-art automatic straw production line is designed to make straw production easier, faster, and more efficient than ever before. Moreover, our production line is designed to be cost-effective, so you can save money and labor while still getting the highest quality straws, tubes, and sticks.

Get The Best Straw Production Solutions Right Now!

What's Your Industry? What Product Do You Make?

No matter what your application is, you’ll get the best solution from Marrow.

Applications:

1. Food industry: beverage straws, sugar sticks, coffee stir sticks, oral liquid medicine straws, etc.

2. Other industries: signature pen refills, nozzle tubes, balloon sticks, small flag sticks, cotton swab sticks, medical tubes, etc.

With 30+ years of experience in straw-making machines R&D, our state-of-the-art automatic straw production line is designed to make straw production easier, faster, and more efficient than ever before. Moreover, our production line is designed to be cost-effective, so you can save money and labor while still getting the highest quality straws, tubes, and sticks.

Straw Examples By Marrow Automatic Straw Production Line

Machines For Every Stage Of Straw Making

No matter what problem you encounter in any stage of straw production, we can solve it for you.

Why Choose Marrow

For many years, Marrow has been developing high-quality, high-efficient, and economic straw production machines to promote the development of the straw production industry. We take pride in helping grow your business.

- Quality Parts For Machines

- Patents & Certificates

- On-site/On-line Technical Support & Training

Customer Reviews

With over 1000+ 5-Star reviews, Marrow has the highest ratings in the industry.We Have Served For 1000+ Straw Production Businesses In The World.

How Does PLA Straw Production Line Work?

PLA straw production lines typically involve a series of processes, including straw extrusion, cooling, and cutting.

Here’s a general overview of how a PLA straws production line works:

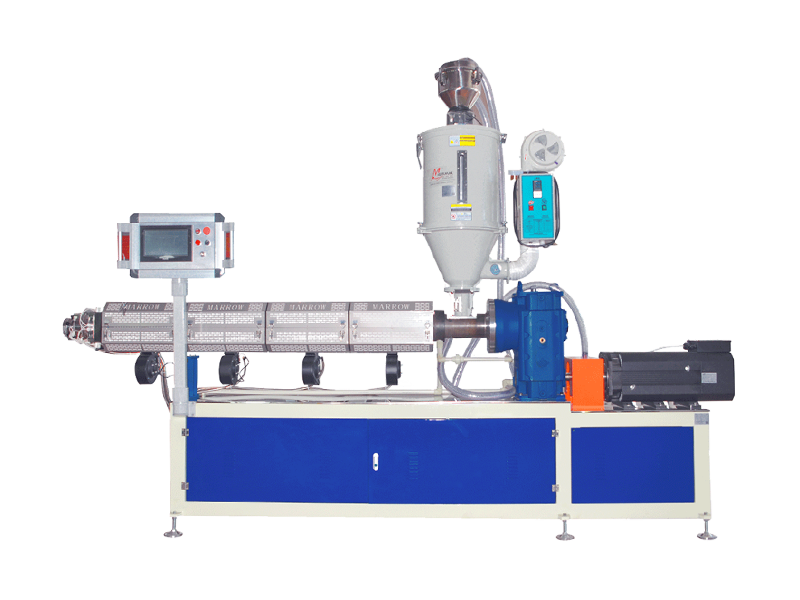

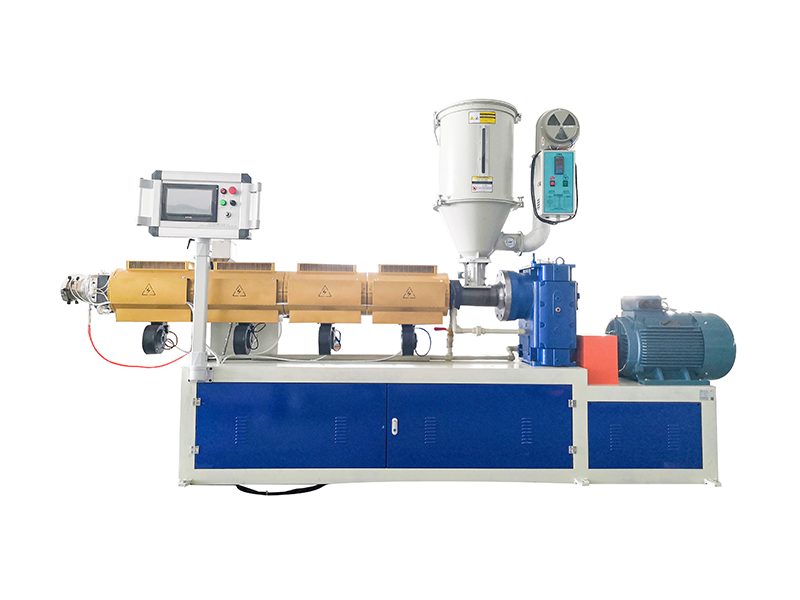

The Main Extruder refers to the PLA straw extrusion machine, which is primarily used to extrude and shape PLA straw material. The straw material is fed from the hopper into the barrel with a screw inside. The screw functions to heat and melt the straw material, while also mixing and homogenizing it to achieve full plasticization. We use our self-developed screw for our straw extrusion machine, which is designed based on the characteristics of PLA material and over 20 years of experience in straw machine production and research. We have secured multiple patents for our innovative screw design. With a length-to-diameter ratio of 33:1, this screw is capable of handling PLA material and a wide range of straw materials available in the market. It allows for precise control over the properties of the extruded material, ensuring consistent output throughout the production process.

After extrusion, the straws are in a hot state. To achieve their desired shape, a cooling water tank, referred to as Vacuum Calibration and Cooling, is utilized. This tank effectively cools down the extruded straws, enabling them to solidify and maintain their desired form.

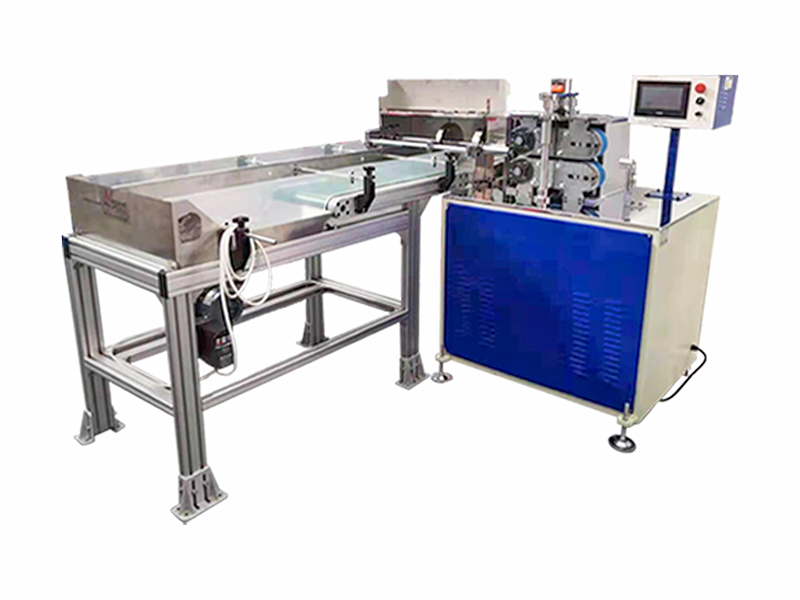

The straws are cut using a Haul-off and Cutter machine, and the length of the produced straws is regulated by adjusting the traction speed and cutting speed of the machine.

Following the cutting process, the diameter, length, wall thickness, or weight of the cut straws are measured manually. If they meet the production requirements, they are deemed to be essentially qualified.

At this stage, the production of straight straws is completed.

If there is a requirement to produce bent straws using PLA material, an additional step of straw forming is introduced after Step 3. Cutting. The process of forming flexible straws involves the use of a specialized straw-forming machine. Different shapes of straws necessitate the use of corresponding machines designed specifically for those shapes. For instance, a Z-shaped straw-forming machine is employed for Z-shaped straws, an expandable straw-forming machine is utilized for expandable straws, and a U-shaped straw-forming machine is employed for U-shaped straws.

The PLA straw crystallization machine is used to subject the produced straws to a secondary high-temperature heating process, which improves the temperature resistance of the PLA straws.

Straight straws, commonly used for milk tea (PLA straws), can be directly packaged after production using a straw-aligning machine and an incline conveyor to transport them to the straw packaging machine.

Milk tea straws are typically packaged individually, so a machine designed for individual straw packaging, such as the ML31D, is used.

After individual straw packaging, if there is a need to group multiple straws together. multiple straw packing machines like ML39E will be used.