PP (polypropylene) and PLA (polylactic acid) are commonly used straw manufacturing materials. Despite both being employed for straw production, their exhibition notable distinctions in various ways. Fueled by the global pursuit of sustainability, the eco-friendly alternative to plastic straws has spurred the advancement of PLA straw manufacturing machinery. This article aims to dissect the variances between PP and PLA straw manufacturing machines, elucidating disparities encompassing material composition, production processes, durability, cost analysis, environmental footprint, and more.

To comprehend the disparity between PP and PLA straw-making machines, it’s imperative to grasp the nature of these 2 straw types:

What is PP straw-making machine?

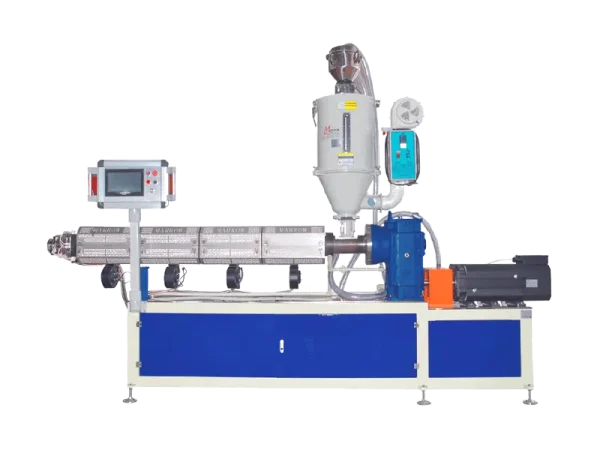

PP straw-making machines, on the other hand, produce straws using polypropylene, a thermoplastic polymer known for its durability and flexibility. PP straws are widely used in the food and beverage industry due to their low cost and versatility.

What is a PLA straw-making machine?

PLA straw-making machines are engineered to craft straws from polylactic acid, a biodegradable and compostable material sourced from renewable resources like corn starch or sugar cane. These machines employ a process of extruding PLA pellets into slender tubes, subsequently trimming and molding them into straws of diverse sizes and configurations.

Advantages of PP straw-making machine

One of the main advantages of the PP straw machine is the economy of the PP material. Polypropylene is a cost-effective option for high-volume production of straws, making PP straws a popular choice for businesses looking for an economical solution.

Advantages of PLA straw machine

One significant benefit of PLA straw machines lies in their eco-friendliness. PLA originates from renewable sources and naturally decomposes, offering a sustainable alternative to conventional plastics. Moreover, PLA straws boast strength and resilience, capable of enduring high temperatures, rendering them suitable for both hot and cold beverages.

Materials used in production differ

Aspect | PP straw-making Machine | PLA straw-making Machine |

Raw Material | Polypropylene (PP) | Polylactic Acid (PLA) |

Biodegradability | Non-biodegradable | Biodegradable |

Environmental Impact | Non-renewable resource | Derived from renewable resources |

End-of-life disposal | Conventional waste management | Compostable or biodegradable waste management |

Production principles and processes differ

- PP Straw Manufacturing Machine: PP straws are typically produced using extrusion and molding processes. During extrusion, molten polypropylene resin is forced through a mold to form continuous tubes. The tube is then cooled and cut into desired lengths, followed by molding and finishing processes. This process allows for the production of a large number of PP straws in a short amount of time.

- PLA Straw Manufacturing Machine: PLA straws are manufactured using similar extrusion and molding techniques. However, the PLA straw manufacturing machine employs more environmentally friendly materials and gentler methods. The straws are not made from PP resin but from PLA pellets made from corn starch or sugarcane, melted and extruded. The subsequent processes still resemble those of PP straw production, including cooling, cutting, and molding. However, the cooling process is gentler to prevent the straws from becoming too brittle.

Production efficiency and cost differ

Aspect | PP straw-making Machine | PLA straw-making Machine |

Production Speed | Generally higher | Slightly lower than the PP straw-making machine, thanks to mature technology it can achieve 1800pcs/min |

Equipment Cost | Moderate | Slightly higher |

Material Cost | Relatively lower | Slightly higher due to PLA pellets |

Market Demand | Widespread use in various industries | Growing demand due to eco-conscious consumers |

Different market applications

- PP straw-making machine: PP straws are widely used in the food and beverage industry, including restaurants, cafes, and fast food chains. Their affordability, durability, and wide availability make them the first choice for many institutions.

- PLA straw-making machine: They are witnessing a surge in popularity, particularly among environmentally conscious consumers and businesses, as the adoption of PLA straws continues to rise steadily. These straws are utilized in the market much like PP straws but offer the added advantage of being biodegradable, aligning with sustainability objectives.

Whether you want highly efficient PP straw-making machines or biodegradable PLA straw-making machines, Marrow can provide you with high-quality straw-making machines.