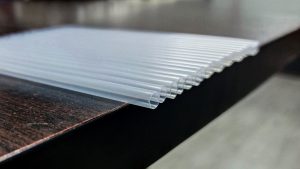

Model ML11 is a tube extrusion line, composed of extruder and die, size setting and water cooling unit, haul-off unit, rotary cutter unit. The series machines can produce all kinds of drinking straw with one color, medical pipe, all the machine’s controls base with the control elements ergonomically adapted to permit easy operation.

Applications Of PP Plastic Drinking Straw Making Machine:

Drinking industry: drinking straw, lollipop, coffe stick, oral liquid straw

Other industry: signature refill, cotton swab stick, medical tube, perfume pipe, balloon pole, flag pole

Specifications PP Straw Making Machine:

| Model | ML11 | |

| Feature | Material | PP PE |

| Color | 1 | |

| Straw diameter | φ3.0 ~ φ12 mm | |

| Thickness | 0.10 ~ 0.35 mm | |

| Straw length | 80 ~ 300 mm | |

| Capability | 400 ~ 1800 pcs/min | |

| Extruding output range | 20 ~ 40 kgs/hr | |

| Extruder | Main Screw diameter | φ50 mm ( BM Screw) |

| Screw L/D | 28 : 1 | |

| Main driving motor | 11 Kw (VFD) | |

| Gearbox | ZLY133 | |

| Automatic thermo-controller | 5 sets | |

| Heating power | 8.1kw | |

| Water tank | Forming device | 1 set |

| Vacuum Pump motor | 1.1 kw(choose) | |

| Water storage tank | (length)3400 mm /304 Steel stainless | |

| Base frame material | (304 Steel stainless) | |

| Blow dry device | 1 set | |

| Take up & Cutting Unit | Take up unit | 1 set |

| Motor | 0.75kW×1(VFD) | |

| Cutting knife unit | 1 set | |

| Motor | 0.75kW×1(VFD) | |

| Angle of port | 90°/60°/45° | |

| Digital counter | 1 set | |

| Others | Air compressor | 1.5kw(choose) |

| Dimension LxWxH | 8m×0.9m×1.6 m | |

| Machine weight | 1800 kgs | |

Technical Features Of PP Straw Making Machine:

1.The extrusion die can be special designed and easy exchanged to produce pipe and shaping stuff.

2.Water bath in stainless steel can be adjusted in three planes.

3.The haul-off unit can be belt or rollers, it is customizable. Fitted with double rotary cutter. Cut angle: 90°/45°, 90°/60°.

4.Conveyor device(you may select if you want).