Properly cleaning the screw can prevent material buildup, ensure consistent product quality, and extend the machine’s lifespan. As a professional PLA straw making machine manufacturer, Marrow will provide you with efficient and expert tips for cleaning the screws of your PLA straw making machine.

4 Steps to Cleaning the Screw of PLA Straw Making Machine

Step1: Preliminary Preparation

First, you must prepare the necessary tools and materials. You will need a set of high-quality cleaning brushes, a non-abrasive cloth, and a specialized cleaning solution designed for PLA machines. Ensure the machine is powered off and has cooled down to a safe temperature before beginning the cleaning process.

Step2: Disassembly

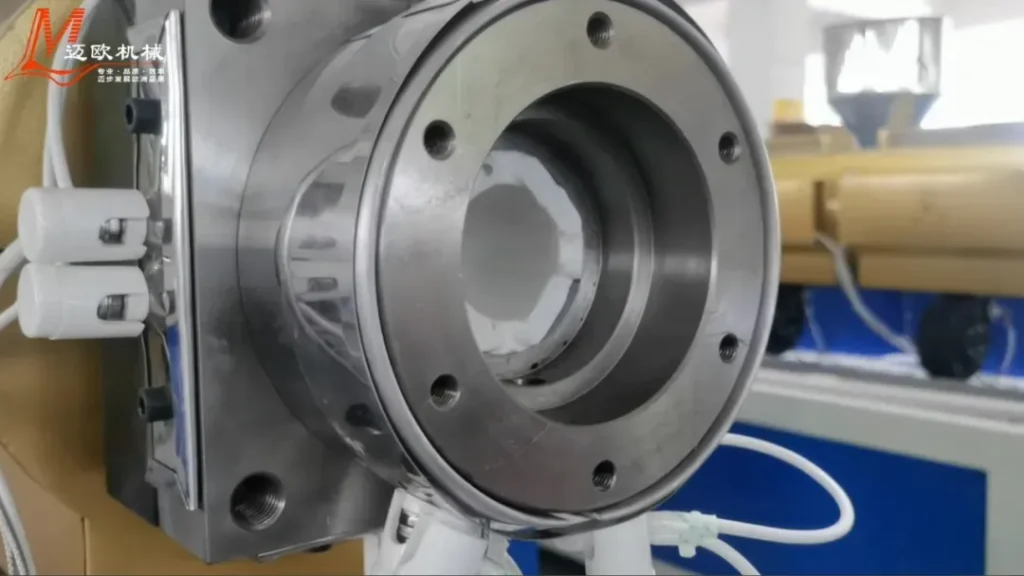

Carefully use tools to dismantle the mold base, paying attention to the order and orientation of each component. Expose the entire barrel screw.

Step3: Cleaning Process

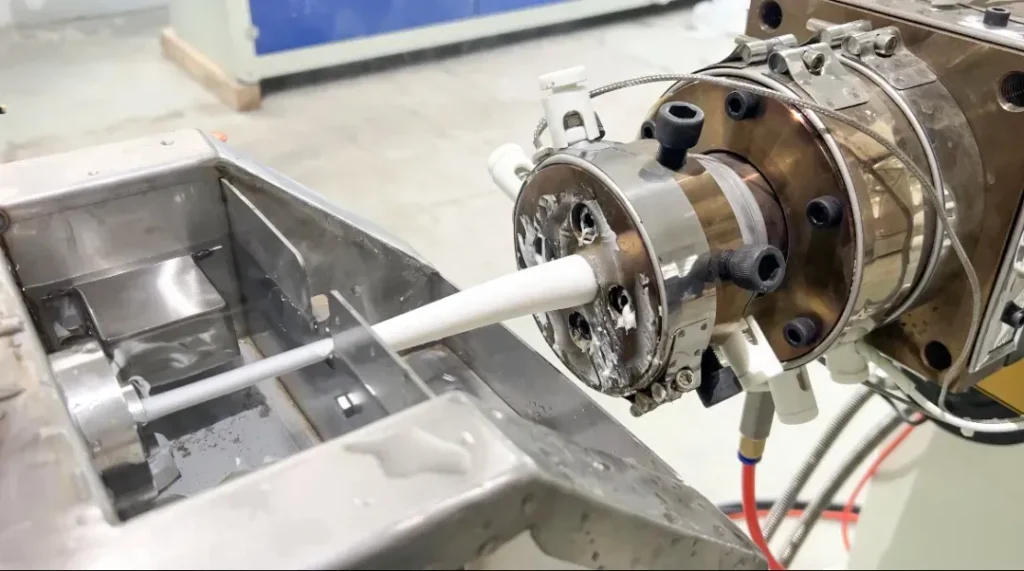

During the cleaning process, we need to raise the temperature and run the straw extruder. Be careful not to overheat. Clean out the PLA material from inside the screw.

At the rear end of the barrel screw, use a hard metal rod to tap the screw until its head is exposed. This tapping helps to remove the semi-molten PLA material from the screw.

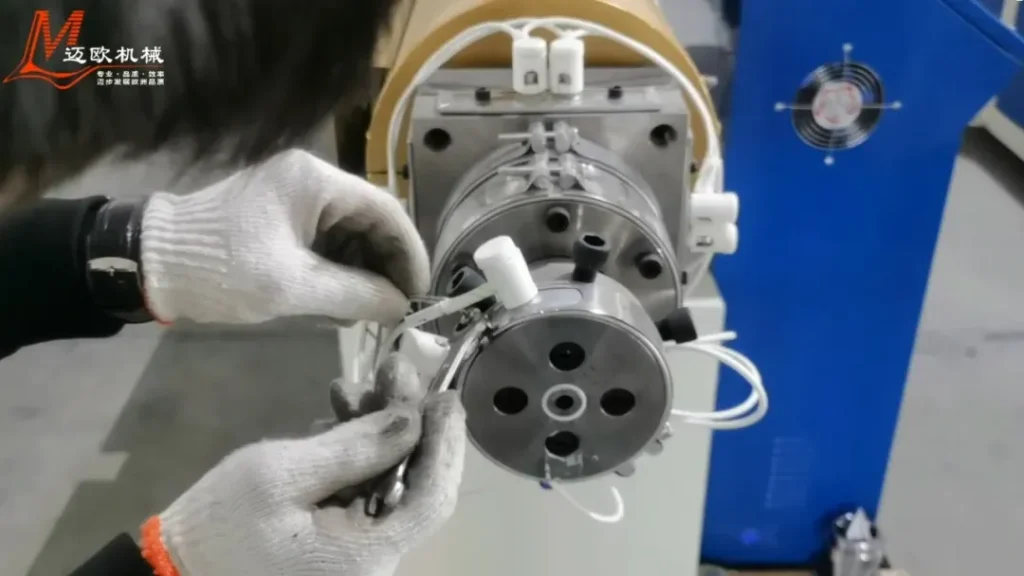

Wrap the head of the screw with a wire. One person should tap while the other pulls. Through this process of tapping and pulling, the remaining PLA material on the screw can be cleaned off.

You can also use suitable cleaning solvents recommended by the machine manufacturer. Avoid using harsh chemicals that may corrode or damage the screw. PLA is biodegradable, so it may dissolve in solvents like ethyl acetate.

Step4: Reassembly and Testing

Once the entire screw is removed, carefully inspect it to ensure all PLA material has been cleaned off. Reassemble the screw back into the machine in the original direction, securing the corresponding parts. Carefully check the alignment and tightness of each component, and reinstall the mold base. After reassembly, run a test cycle to verify that the machine is operating normally and that the screw is performing optimally.

By following these steps and tips, you can ensure that your PLA straw machine operates efficiently and produces high-quality products. Regular maintenance, including proper cleaning of the screw, is essential for the longevity and reliability of the machine.

If you’re still unclear about how to clean the PLA straw extruder, please feel free to contact us. We’re here to provide professional assistance and support.