For straw enterprise production, a straw extruder with stable extrusion can ensure consistent quality of produced straws, improve production efficiency, and reduce the scrap rate. The increasing awareness of sustainable development and environmental protection has promoted the development of polyhydroxyalkanoate (PHA) straws. As a straw extruder that uses renewable resources as raw materials, the stability of the PHA straw extruder is crucial. This article will show you what kind of PHA straw extruder can provide a stable extrusion effect.

Main Features of Stable PHA Straw Extruder

1. Continuous temperature control

Maintaining a constant temperature is critical for the stability of PHA during extrusion. PHA has a narrow processing window, and fluctuations can result in spoiled or poor-quality straws. The advanced extrusion machine is equipped with a precise temperature control system that can monitor and adjust the temperature in real time.

Marrow is equipped with a far-infrared heating ring in its straw extruder, which not only allows the plastic pellets to be evenly heated and completely melted, but also the heating temperature is smoother. The result is consistent straw quality and reduced material waste.

2. Special screw design

The use of special screw designs, such as the pineapple nail + BM separation type patented technology screw, ensures that the straw material enters the screw after being fully plasticized and extruded. Not only is the extrusion stable, but the surface of the straw produced in this way is clean, smooth and of good quality. !

Marrow straw extruder manufacturer has specially developed a special screw design to greatly improve production efficiency and significantly reduce the scrap rate.

3. Residence Time Distribution (RTD)

Optimizing RTD ensures uniform polymer processing and minimizes residence time variation, which is critical to achieving consistent product quality. Efficient mixing element and mold design play a key role in controlling RTD and improving process stability.

Basic Components of PHA Straw Extruder

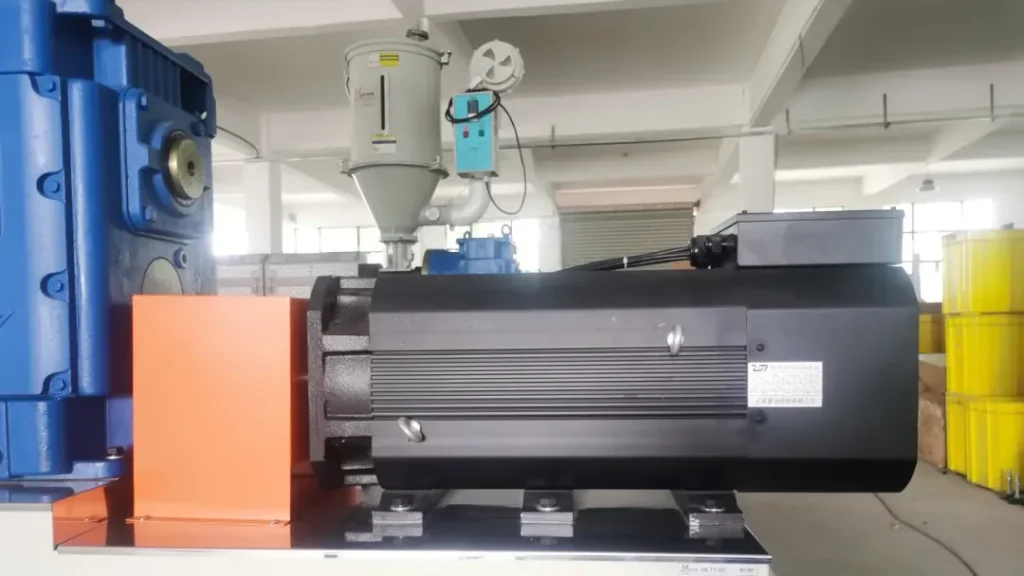

- Servo motor: The motor is the core component of the straw extruder, and its performance directly affects the stability of the extrusion. Choose a straw extruder equipped with a servo motor, which provides precise control and stable power output. It can ensure that plastic particles are melted evenly and avoid irregular shapes or clogging problems caused by power fluctuations.

- Screw Elements: Screw profiles customized to PHA processing requirements enhance mixing, melting and conveying capabilities to optimize extrusion efficiency and product quality.

- Mold Design: Precision-designed molds with adjustable parameters facilitate the production of straws in a variety of geometries and sizes, providing versatility and flexibility in product design.

- Filtration System: High-performance filtration prevents impurities and contaminants from affecting product quality, ensuring pure PHA straws that are defect-free.

Innovative Design Considerations for PHA Straw Extruders

- Modular configurations: Modular extrusion systems offer scalability and flexibility, allowing operators to tailor production lines to specific throughput requirements and product variations.

- Intelligent control: Integrated IoT sensors and automation technology can monitor and control extrusion parameters in real time, thereby improving process reliability and efficiency.

- Energy Efficiency: Incorporates energy-saving features such as heat recovery systems and optimized heating elements to minimize energy consumption and reduce operating costs, consistent with sustainable manufacturing practices.

Conclusion

Producing high-quality PHA straws requires an extruder with stability, precision and efficiency. Key features such as consistent temperature control, efficient screw design and powerful cooling systems are critical. In addition, components such as high-precision barrels, advanced control systems and high-quality mold heads also play a vital role. In short, if you want to purchase a straw extruder with stable extrusion, you should pay attention to the comprehensive comparison of machine configurations and choose a straw extruder that meets your production needs.

If you are looking for a stable straw extruder, please contact Marrow straw extruder experts, we will answer your confusion and provide you with a high-quality and stable straw extruder.