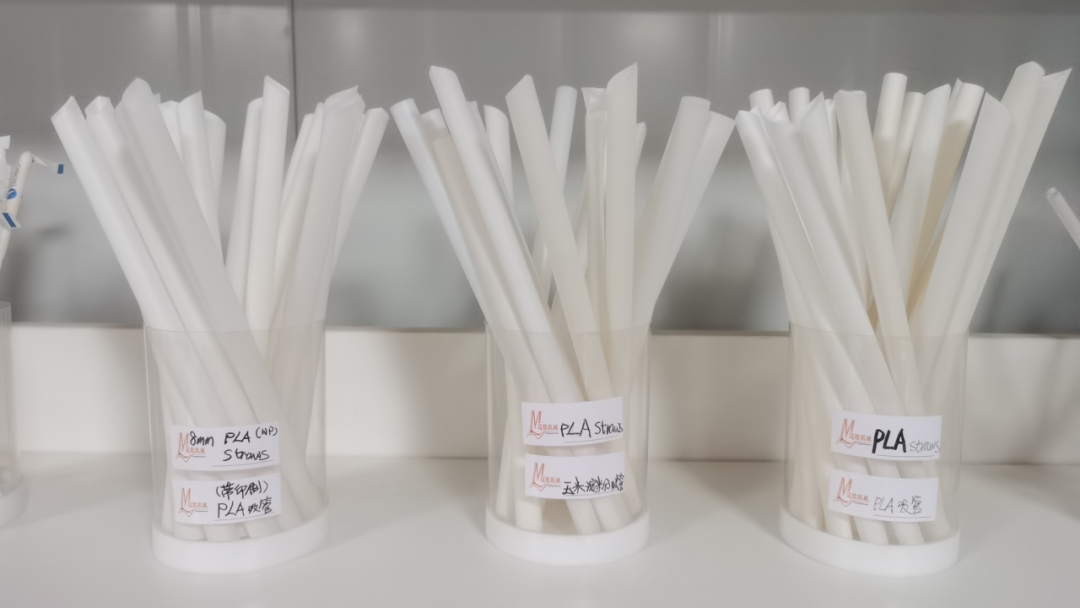

PLA straws, as a sustainable alternative to traditional plastic straws, better meet the demands of environmental protection and sustainable development. PLA, the material used to produce PLA straws, is a biodegradable and bioactive thermoplastic derived from renewable resources such as corn starch or sugarcane. To produce high-quality PLA straws, selecting the appropriate extruder is crucial.

There are 5 key aspects to consider when determining the most suitable straw extruder for producing PLA straws.

1.Choosing the Appropriate Screw Length-to-Diameter Ratio

Mr. Ling Hongjun, an expert in straw machinery, developed a screw with a length-to-diameter ratio of 33:1, featuring a BM separation type and pineapple pin structure design. This design meets the low-temperature operating requirements of PLA and improves the plasticizing effect of PLA material. Compared to single-screw extruders, twin-screw extruders offer better mixing and more consistent output, which is beneficial for maintaining the uniformity of PLA straws.

2.Actual Output of the Straw Extruder

A high-output, high-quality straw extruder should achieve an extrusion rate of over 80 kilograms per hour once heated to the appropriate temperature. This level of production efficiency ensures the efficient and stable production of PLA straws, making it the most suitable choice for PLA straw manufacturing.

3.Configuration of the Straw Extruder

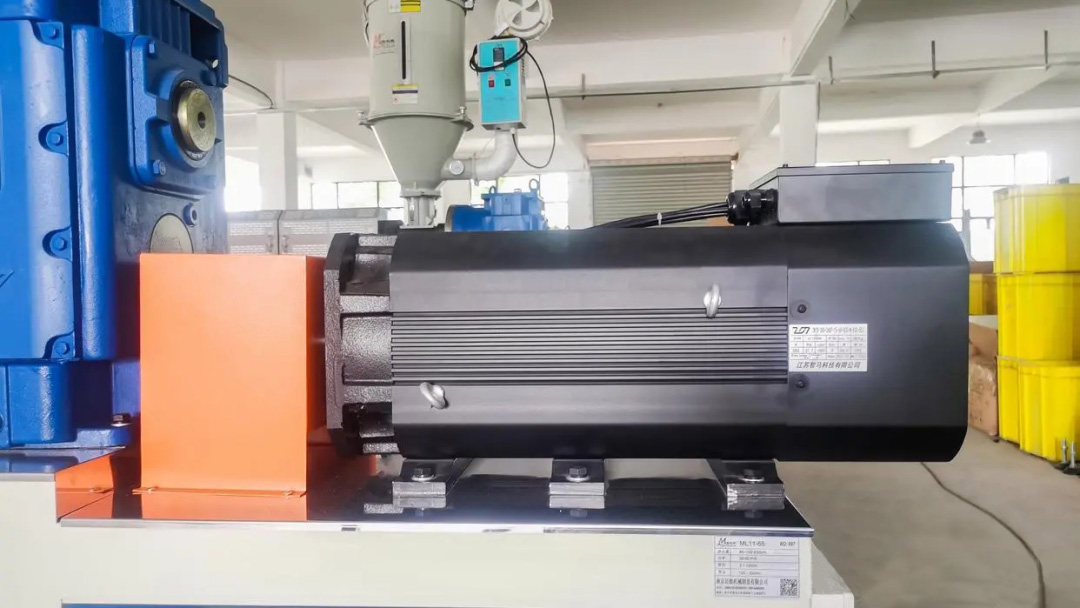

A straw extruder equipped with a servo motor drive and direct connection structure avoids issues such as belt slippage and aging that occur with long-term use of triangular belts and standard motors. This configuration ensures the stability of the extrusion speed, thereby guaranteeing the quality of PLA straws.

4.Temperature Control

Compared to other plastics, PLA has a relatively low melting point (approximately 150-160°C). A straw extruder with precise temperature control is crucial for preventing the degradation of PLA.

5.Automation and Control Systems

- Advanced Control Systems: Modern extruders equipped with PLC (Programmable Logic Controller) systems allow for precise control over the extrusion process, ensuring consistent quality and reducing waste.

- Automation: Automated systems can streamline the production process, reduce labor costs, and improve efficiency. Features like automatic feeding, cutting, and packaging can significantly enhance productivity.

In summary, selecting the appropriate straw extruder provides reliable technical support for producing high-quality PLA straws.

Recommended Straw Extruder Models

The Marrow ML13 extruder is renowned for its high performance and versatility, featuring excellent blending capabilities and precise temperature control. This makes it an ideal choice for producing PLA straws.

Model ML12 PLA extrusion line is a tube extrusion line, composed of PLA extruder and die, size setting and water cooling unit, haul-off unit, servo motor rotary cutter unit, special patent technical design screw L: D(33:1) for PLA material, also PP material can be used.

The series of machines can produce various types of PLA and PP drinking straws as well as medical pipes. All machines feature PLC and touch screen control elements, designed ergonomically for easy operation. All production data can be transferred to the central office via NCC. With a Wi-Fi function, the PLC system can be monitored and updated over the internet.

If you are searching for high-quality straw extrusion machines for your PLA straw industry, we welcome you to contact us. As experts in straw extrusion machines, Marrow will provide you with an ideal straw extruder tailored to your requirements.