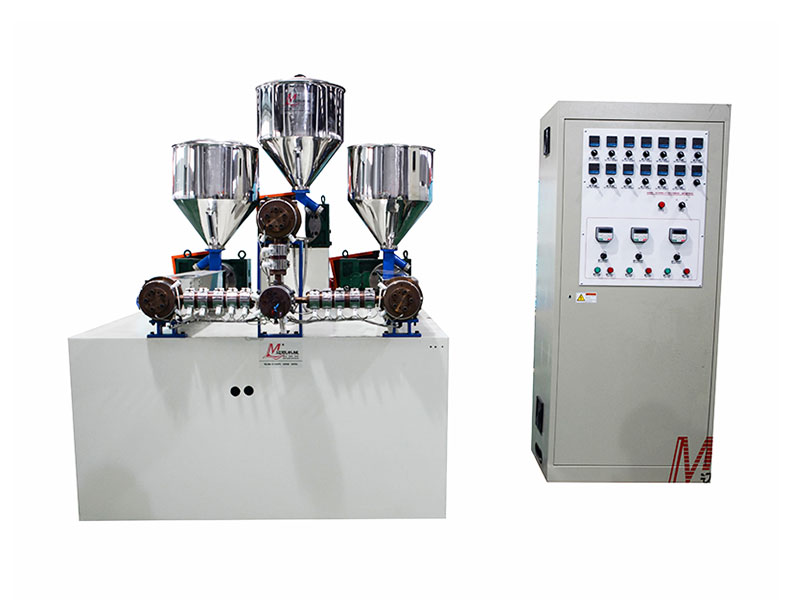

Beverage Straw Extruder

Plastic Straw Making Machines For Sale

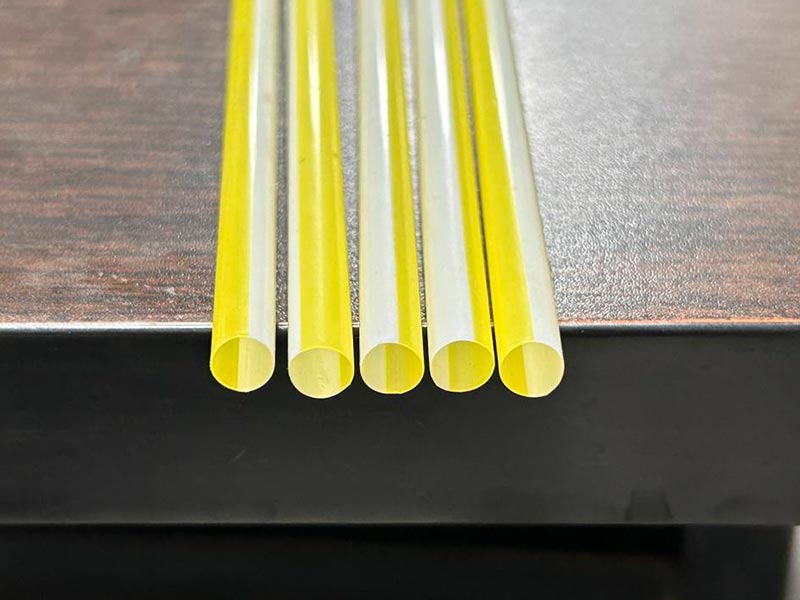

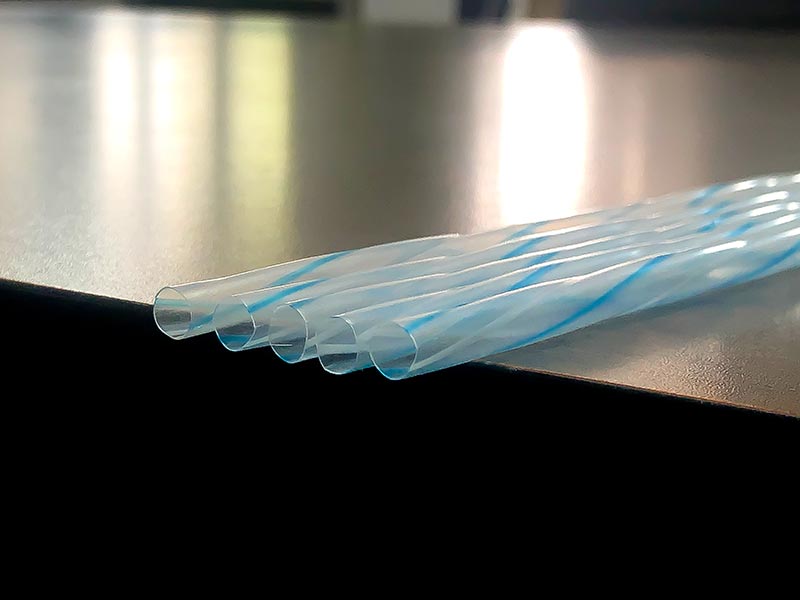

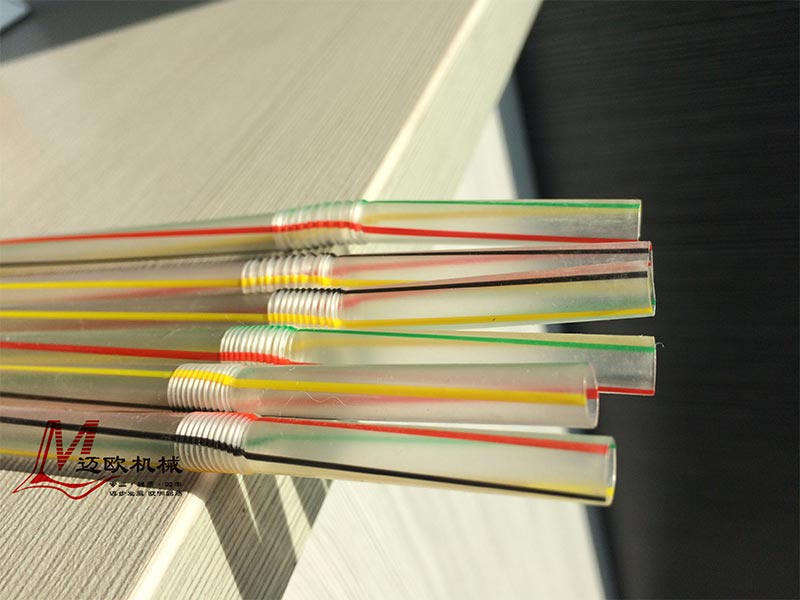

Plastic straw extruder is the most important machine among the plastic straw making machines that people talk about. Our machine can produce drinking straws in single, two, three, and five colors. Regarding the color preferences for the beverage straws, our machines can meet the requirements of most of your customers. You’re welcome to take a look at the plastic straw extrusion machines you’re interested in, or you can reach out to us directly. We’ll get back to you as soon as possible.

| Model | ML11 | ML12 | ML13 | ML15 | ML12A | ML13A | ||

| Feature | Material | PP PE | PP | PP PE | PP | |||

| Color | 1 | 2 | 3 | 5 | 2 | 3 | ||

| Straw diameter | φ3.0 ~ φ12 mm | |||||||

| Thickness | 0.10 ~ 0.35 mm | |||||||

| Straw length | 80 ~ 300 mm | |||||||

| Capability | 400 ~ 1800 pcs/min | |||||||

| Extruding output range | 20~40 kgs/hr | 20~45 kgs/hr | 30~60 kgs/hr | |||||

| Extruder | Main Screw diameter | φ50 mm ( BM Screw) | φ45 mm×2 (BM Screw) | φ45 mm×3 (BM Screw) | ||||

| Screw L/D | 28:01:00 | |||||||

| Main driving motor | 11 Kw (VFD) | 7.5 Kw×2 (VFD) | 7.5 Kw×3 (VFD) | |||||

| Automatic thermo-controller | 5 sets | 8 sets | 11 sets | 11 sets | 11sets | 16sets | ||

| Heating power | 8.1kw | 11.63 kw | 14.75 kw | 20.8 kw | 14 kw | 18 kw | ||

| Water tank | Forming device | 1 set | ||||||

| Vacuum Pump Motor | 1.1 kw(choose) | |||||||

| Water storage tank | (length)3400 mm /304 Steel stainless | (length)4800 mm /304 Steel stainless | ||||||

| Base frame material | (304 Steel stainless) | |||||||

| Take up & Cutting Unit | Take up unit | 1 set | ||||||

| Motor | 0.75kW×1(VFD) | |||||||

| Cutting knife unit | 1 set | |||||||

| Angle of port | 90°/60°/45° | |||||||

| Others | Air compressor | 1.5kw(choose) | ||||||

| Dimension LxWxH | 8×0.9×1.6 (m) | 8×1.2×1.6 (m) | 8×1.4×1.6 (m) | 8×1.5×1.6 (m) | 8×1.2×1.6 (m) | 8×1.5×1.6 (m) | ||

| Machine weight | 1800 kgs | 2100 kgs | 2300 kgs | 2800 kgs | 2800 kgs | 3400 kgs | ||

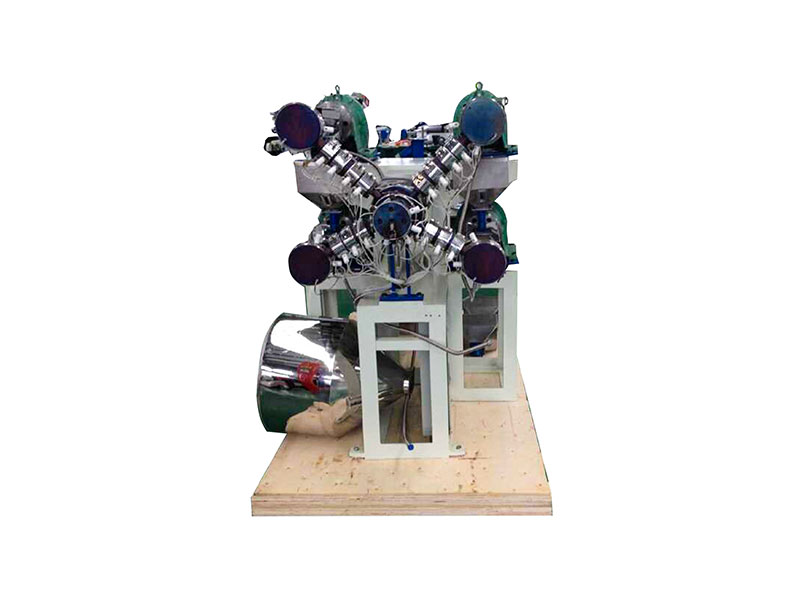

Advantages Of Marrow Drinking Straw Extruder

Special patent technical design screw L:D (33:1) for PLA material,all straw materials on the market are applicable.

Extrusion capacity up to 100kg/h(1800 straws /min)

The service life of the machine is more than 20 years

30kw high efficient & saving energy servo motor, effectively reduce the grammage error of straws, and ensure the efficient and stable production of PLA straws.

The use of a number of patented technology design, improve the comprehensive performance of the straw machines, to ensure the stable and efficient operation of the straw making machines.

After the straw machine arrives at the straw factory, it only needs to go through a simple trial machine to produce qualified straws, which greatly reduces the waste of straw raw materials in the process of trial machine.

Experienced operators to provide services on site.

Straw machine experts teach straw machine application methods, professional video training courses for online training.

Why Choose Marrow

For many years, Marrow has been developing high-quality, high-efficient, and economic straw production machines to promote the development of the straw production industry. We take pride in helping grow your business.

- Quality Parts For Machines

- Patents & Certificates

- On-site/On-line Technical Support & Training

Customer Reviews

With over 1000+ 5-Star reviews, Marrow has the highest ratings in the industry.We Have Served For 1000+ Straw Production Businesses In The World.

Beverage Straw Extruder fails to extrude materials? What Are The Reasons? How To Address This Problem?

1. Check if the beverage straw machine and inverter are running.

2. Check if there is material loaded into the feeding inlet of the straw extruder.

3. Check if the feeding inlet of the plastic straw extruder is blocked. If the water cooler was not shut off the previous day, it can lead to blockage at the feeding inlet, making it difficult to feed materials.

4. If none of the previously mentioned situations are present, the issue could be attributed to the way the straw making machine equipment was assembled during manufacturing, resulting in a narrow gap between the mold channels. In this case, just replace the mold head.

If you have performed the aforementioned checks and adjustments, in most cases, the beverage straw extruder should no longer fail to extrude straw materials. We provide training courses on the operation and maintenance of straw making machines, which can assist you in combining theoretical knowledge with hands-on practical exercises to help resolve production-related issues. Feel free to consult us for any other beverage straw making machine-related or straw production-related inquiries you may have!